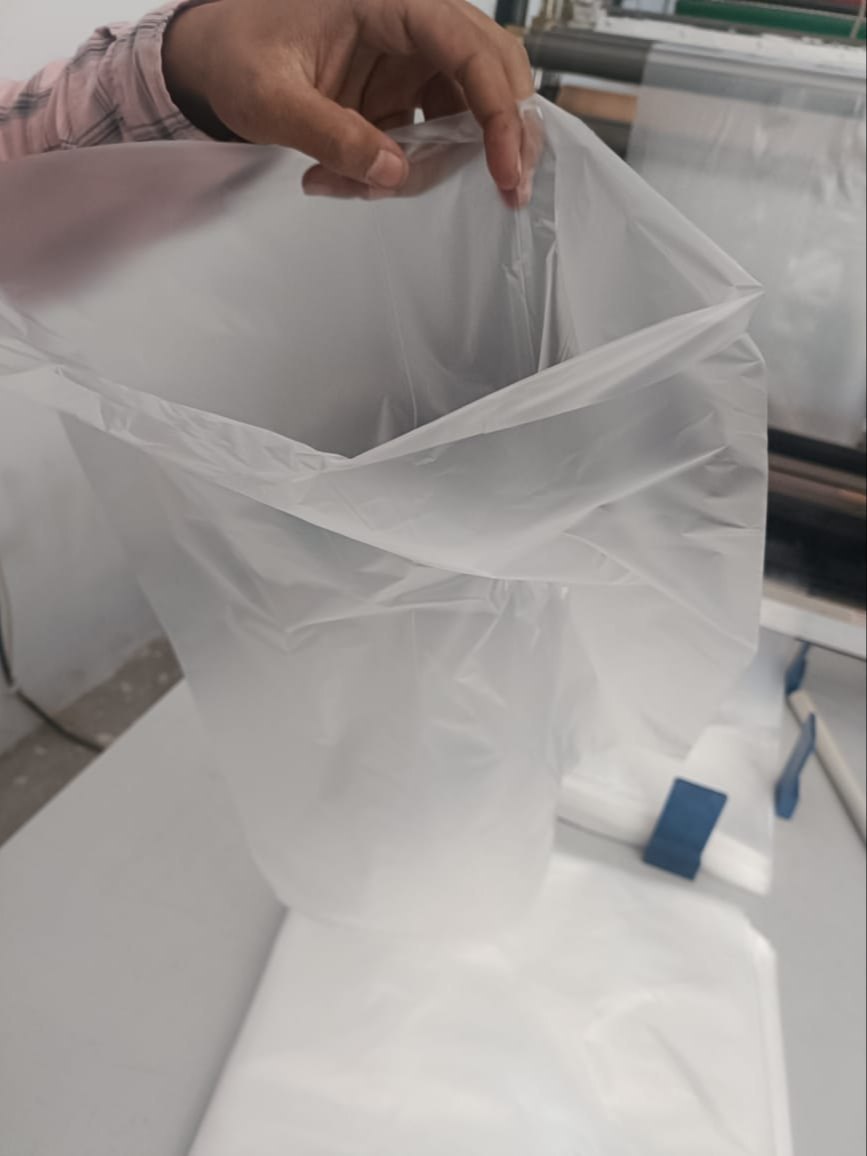

HM (High Molecular) liner bags, made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), have specific thermal properties that influence their performance under extreme temperatures.

Heat Resistance

- Heat Tolerance: HM liner bags typically withstand temperatures up to 120°C (248°F) for short periods. Beyond this, the material may start to deform or lose its structural integrity.

- Applications: They are not ideal for handling very hot substances or exposure to prolonged high temperatures (like industrial ovens), as this could weaken the material or cause it to melt.

Cold Resistance

- Cold Tolerance: HM liner bags are highly resistant to cold and can endure temperatures as low as -40°C (-40°F) without becoming brittle. This makes them suitable for use in cold storage or transporting frozen goods.

- Flexibility: Even at low temperatures, HM bags remain flexible, which is crucial for handling and packing in cold environments.

Enhancements

- Additives: To improve heat or cold resistance, specialized additives can be incorporated during manufacturing.

- Multi-layer Design: Some HM liners are made with multi-layer structures that offer better thermal performance.

Limitations

For extreme heat applications, alternative materials like polypropylene (PP) or specialty-engineered plastics may be more suitable. However, for most standard industrial, storage, and transportation uses, HM liner bags provide excellent performance within their thermal range.

Behavior Under Severe Heat

- Thermal Softening Point: HM liner bags (HDPE or LDPE) have a melting point ranging from 120°C to 135°C for HDPE and 105°C to 115°C for LDPE. Prolonged exposure to temperatures close to these limits can cause:

- Warping or deformation.

- Loss of strength and potential tearing.

- Application Limitations:

- Not suitable for packaging hot liquids or products right out of industrial processes (like hot molten materials).

- Avoid direct exposure to heat sources such as sunlight in extreme climates, as this can accelerate material degradation.

- UV Sensitivity: Continuous exposure to sunlight can degrade the bags over time, but UV stabilizers can be added during manufacturing to enhance their durability in outdoor heat.

Performance in Severe Cold

- Excellent Cold Resistance:

- HM liners remain highly flexible and do not crack under extremely low temperatures, down to -40°C or lower, depending on the material blend.

- Impact Resistance:

- At cold temperatures, many plastics become brittle, but HM bags maintain their toughness and elasticity, making them ideal for cold storage and transport. Quality-assured raw materials and cutting-edge technology are used in the production of HM Plastic Roll, which is available here.

- Applications:

- Widely used in freezer storage industries (frozen foods, pharmaceuticals).

- Suitable for handling cryogenic substances, provided temperatures stay within their performance range.

Enhancements for Better Performance

- Heat Stabilizers: Added during production to improve heat resistance for applications requiring higher thermal stability.

- Cold Flow Additives: Reduce brittleness at ultra-low temperatures.

- Barrier Properties:

- To prevent moisture ingress or heat transfer, multi-layer HM liners with thermal insulation properties are used.

- Customization: Liners can be tailored for specific industries, such as food-grade bags for cold storage or liners for transporting semi-hot items.

Applications Across Temperature Extremes

- Severe Heat:

- Packaging products in warm environments, like agriculture (grains, fertilizers) or chemical industries.

- Severe Cold:

- Used in frozen food packaging, seafood exports, vaccines and medical product transport, and even industrial applications like storage of ice or cryogenic goods.

Limitations to Consider

- Not Ideal for Prolonged High Heat: HM liners are not designed to endure long-term exposure to high-temperature industrial processes.

- Condensation in Cold Storage: In cold environments, if the temperature transitions frequently, condensation may occur, requiring additional handling or double-lining solutions to maintain product quality.

Material Composition and Its Impact on Thermal Performance

HM liner bags are predominantly made from HDPE or LDPE, each with distinct thermal characteristics that affect their performance under severe heat or cold:

HDPE (High-Density Polyethylene)

- Heat Resistance: Better heat resistance than LDPE, withstanding temperatures up to 120°C for short durations.

- Cold Resistance: Retains flexibility and strength at temperatures as low as -40°C.

- Applications: Ideal for industrial packaging where mechanical strength and moderate heat resistance are required.

LDPE (Low-Density Polyethylene)

- Heat Resistance: Lower heat tolerance compared to HDPE, typically around 105°C.

- Cold Resistance: Even more flexible than HDPE at sub-zero temperatures, making it ideal for deep-freezing applications.

- Applications: Frequently used in food packaging, especially in cold storage or freezer environments, where flexibility and airtightness are critical.

Performance Enhancements Through Advanced Manufacturing

To improve the thermal resilience of HM liner bags, manufacturers can integrate various innovations:

Multi-Layered Films

- Structure: Consist of multiple layers of different materials, each optimized for specific properties (e.g., thermal resistance, barrier protection).

- Benefits:

- Improved insulation against temperature changes.

- Enhanced durability for both hot and cold applications.

Additives and Stabilizers

- Heat Stabilizers: Prolong material life in high-temperature environments by preventing thermal degradation.

- UV Stabilizers: Protect against heat-induced degradation caused by prolonged sun exposure.

- Anti-Oxidants: Prevent breakdown of polymers at elevated temperatures, maintaining bag strength and integrity.

- Cold Flow Improvers: Prevent brittleness at extreme sub-zero temperatures, enhancing flexibility and impact resistance.

Cross-Linking Technology

- Cross-linked polyethylene (PEX) enhances both heat and cold resistance, allowing the bags to maintain their structural integrity across wider temperature ranges.

- Applications: Useful for heavy-duty industrial or hazardous material packaging.

Summary

HM liner bags are robust solutions for a wide range of applications, particularly excelling in cold environments. However, when exposed to high temperatures or extreme environmental conditions, proper modifications (like additives or using alternative materials) should be considered to maximize performance.